Products & Services

Safario Cooling Factory

AC Repair Dubai, AC Maintenance Dubai, Leading Manufacturer of Condenser Coils, Industrial Chillers UAE

Since 1999, Safario Cooling Factory LLC has been maintaining as a leading Manufacturer of Commercial and Industrial HVAC Coils, Chilled Water Coils, Chiller Coils, Steam Coils, Heat Pipes, Heat Exchangers, Immersion Coils, Refrigeration, Air Conditioning, Condenser, Evaporator Coils.

We have been serving all the major OEM companies, electromechanical contracting companies, retailers in UAE and other GCC countries at very competitive prices and quality products. Our Technical Team is always there to guide and install coils which improve the efficiency of the units and reducing power consumption.

Our Quality Assurance Department ensures that each and every coil is tested and approved at every stage of production. Leak tests are carried out with nitrogen giving right kind of air pressure.

We have field staffs who regularly visit sites to take measurement of the coils, wherever coils data are not available.

We have flexible manufacturing and delivery schedules; this helps us to accommodate a client’s emergency requests to produce a coil at early date Safario manufactures air-conditioner evaporators and condensers in any size and capacity in accordance with the customer needs.

These condenser and evaporator coils are usually manufactured with 3/8” tubes. 1/2” and 5/8”. Please refer to the Geometric details.

Engineering and Quality Control

Precision and accuracy of our calculations are provided by a software program by UNILAB Company, which enables our condensers and evaporators work in the most efficient way. The latest version of this software is currently available in our company OEM coils/heat exchangers are the ideal solutions for large volume, price sensitive users who need a high quality, cost effective part.

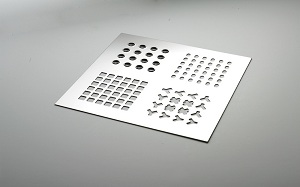

Safario specializes in OEM coils in addition to a wide range of other heat exchangers. OEM coils are either designed or directly manufactured upon customer needs and requirements. A large family of fin geometries makes it easier for our customers to get what they exactly need. 3/8”, ½” or 5/8” coils are manufactured for different application areas from Industrial Refrigeration Sector to a special project that requires durable and reliable solutions.

We have specialized technical teams to replace HVAC heat exchangers, condenser and evaporator coils.

Additionally, we have professional teams to take care of the installation of chillers, package, split and window air conditioners.

Annual Maintenance Contracts – A Planned Preventive Maintenance (PPM) program will safeguard and improve the performance of the air-conditioning equipment. When the AC equipment is well maintained, it will not only save energy and saving your money, it will also increase the efficiency of the units. It will enhance the life of the unit substantially. Our program includes scheduled servicing visits, repairing of the AC units when there are a cooling deficiency and general repairs and technical advice, training of the unit operators at the site, etc.

Safario product covers a different type of coil pattern. You can find all the details of fin Geometries

Copper Tubes:

(OD 9,52 mm (3/8") : With wall thicknesses of 0,35mm plain as standard; 0,40 - 0,50 - 0,70 mm plain or 0,30 / 0,50mm (min.-max.) IGT upon request.

OD 12,70 mm (1/2") : With wall thicknesses of 0,35mm plain as standard; 0,40 - 0,50 - 0,70 mm plain ; 0,35 / 0,61mm (min.-max.) IGT upon request.

OD 15,87 mm(5/8") : With wall thicknesses of 0,40mm plain as standard ; 0,50 - 0,70 - 1,0mm plain upon request.

Tubes have a suitable quality for refrigeration and air conditioning.

FINS

The available tube arrangements and fin properties used are given in details in the following pages. In addition to 8006 H22 aluminum alloy, copper foils and hydrophobic, hydrophilic foils are used upon request.

CASING

Galvanized and aluminum sheets are used as casework materials. Other appropriate materials can be used upon request.

BRAZING MATERIAL

The most appropriate brazing material is chosen according to the application area.

HEADER MATERIALS

Unless otherwise stated, steel manifolds are used for dry coolers, water, and steam coils. For all other products, copper manifolds are used.

Fin Materials

Different type of coatings is applied depending on application areas and corrosion conditions. Coils can be manufactured from copper and hydrophilic fins. Depending on customer request, Heresite Coatings are applied with a warranty of 5 years on-shore and 3 years off-shore.

Compressor Overhauling – Our Compressor overhauling center is specialized in overhauling all type of HVAC compressors. Our Workshop is highly specialized in HVAC equipment repairing. The workshop is under the supervision of well-qualified technicians to ensure that all the activities are properly monitored and configured to meet the superior quality standard. Our Quality Assurance Department is responsible for maintaining the continuous improvement and achievement of the highest quality standards of the services provided.